MIL-DTL-3100H

3.4 Physical and mechanical properties.

3.4.1 Hardness. The hardness [durometer Shore A or International Rubber Hardness

Degrees (IHRD)] of elastomer compounds shall be 70 +7 when tested in accordance with 4.6.3.

3.4.2 Accelerated aging characteristics. After aging 166 hours at 158 degrees

Fahrenheit (°F), within any one specimen, the change in tensile strength shall be not more than

+25 percent (%) and the change in elongation shall be not more than +35% when tested in

accordance with 4.6.3.

3.4.3 Low temperature flexibility. At a temperature of -40°F, the specimen shall show

no evidence of cracks, fissures, or holes visible to the naked eye, or complete separation into two

or more pieces when tested in accordance with 4.6.3.1.

3.5 Performance.

3.5.1 Endurance requirements. The wheel assembly shall evidence no internal or external

failure after rolling under the following conditions; however, no one sample shall be required to

withstand operation under both condition sets a and b (see 4.6.4).

a. For 48 continuous hours at not less than 10 miles per hour (mph) under 100% load

specified in table I and tested as specified in 4.6.4.1.

b. For 6 continuous hours at not less than 30 mph under 120% load specified in

table II and test as specified in 4.6.4.2.

The tires shall exhibit no cracking, chunking, blowout, separation, blister, contamination,

porosity, delamination, or lack of adhesion. Any undercutting shall be not more than 0.25 inch

(in.) deep.

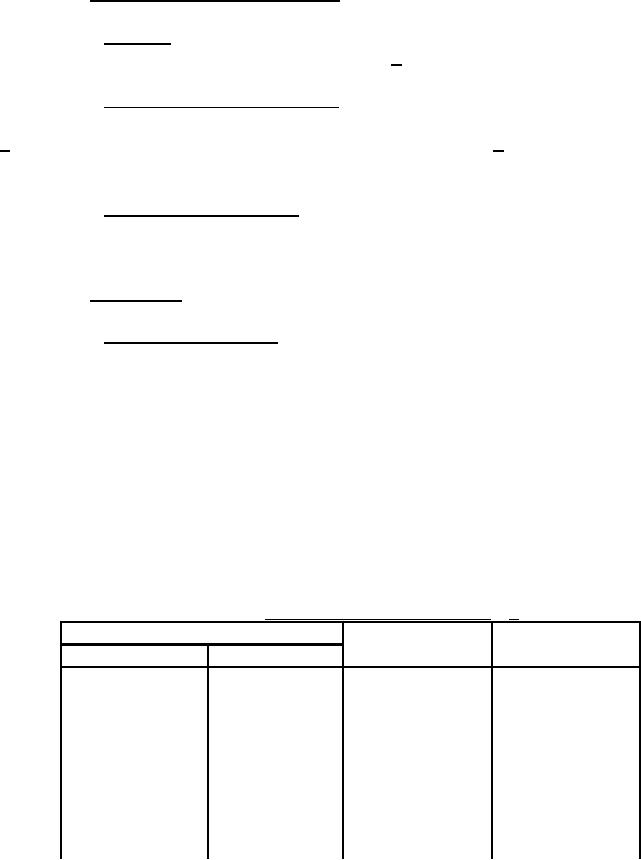

TABLE I. Wheel assembly loads - 10 mph. 1/

Assembly

Pounds per inch

100% load total

Size (nominal)

Part number

of width

pounds (min.)

11 x 3

5636637

385

1155

11 x 3-7/16

12296928

385

1155

12-1/2 x 2-1/2

12292059

452

1582

13-1/2 x 3-1/2

8763030

495

1732

13-1/2 x 3-3/4

8706067

495

1856

22 x 1-3/4

10925778

885

1548

23 x 1-1/4

9092158

935

1168

24 x 2-1/8

11678270

985

2093

24 x 2-1/8

8763350

985

2093

5

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business